Railcar Couplers

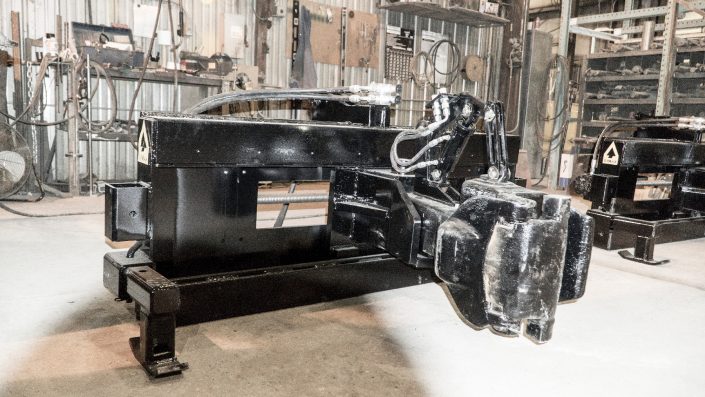

Railcar Couplers for Wheel Loaders and Toolcarriers:

Dymax Railcar Couplers enable operators to use construction and agricultural machinery to move railway cars in yard applications. Available for Wheel Loaders, Tractors and adaptable kits for hi-rail trucks and equipment. Made for situations where rail cars need to be moved with on-site mobile machines, Dymax Railcar Couplers can quickly be adapted to either the front or back of wheel loaders or other machines to make on-site machines more versatile. Put that older wheel machine back into use!

Front Mounted Wheel Loader Models:

- Available with Manual or Hydraulic pin

- Free slide frame with pivot knuckle for non-hi-railed machinery.

- Fixed Knuckle center mounted with pivot

Tractor Models:

- Custom front mounted with pivot knuckle; hydraulic or manual pin

- 3 point hitch (Category 2 and or 3) with manual free slide and hydraulic or manual pin

- 3 point hitch (Category 2 and 3) with hydraulic positioner sideshift and hydraulic or manual pin

Bareback Models:

- Adaptable to a variety of trucks and equipment for working in railway applications. Unimog, Grapple Trucks.

- Adaptable to wheel loaders (Front and Rear)

- *Bareback models require some setup on site prior to use.

Specifications:

| Model Number | Description | Weight (lbs/kg) | |

|---|---|---|---|

| Free Slide Frame – Manual Side Shift | |||

| DX-RCQ-HY-FFS-WL-40 | Rail Car Quick Coupler – Hydraulic – Front Mount Free Slide – Wheel Loader – Class 40 | 2,800 lbs/1,270 kg | |

| DX-RCQ-HY-FFS-WL-50 | Rail Car Quick Coupler – Hydraulic – Front Mount Free Slide – Wheel Loader – Class 50 | 2,800 lbs/1,270 kg | |

| DX-RCQ-HY-FFS-WL-60 | Rail Car Quick Coupler – Hydraulic – Front Mount Free Slide – Wheel Loader – Class 60 | 2,800 lbs/1,270 kg | |

| DX-RCQ-HY-FFS-WL-70 | Rail Car Quick Coupler – Hydraulic – Front Mount Free Slide – Wheel Loader – Class 70 | 2,800 lbs/1,270 kg | |

| DX-RCQ-HY-FFS-WL-80 | Rail Car Quick Coupler – Hydraulic – Front Mount Free Slide – Wheel Loader – Class 80 | 3,200 lbs/1,452 kg | |

| DX-RCQ-HY-FFS-WL-90 | Rail Car Quick Coupler – Hydraulic – Front Mount Free Slide – Wheel Loader – Class 90 | 4,500 lbs/2,041 kg | |

| Center Mounted Fixed Knuckle | |||

| DX-RCQ-HY-FFX-WL-40 | Rail Car Quick Coupler – Hydraulic – Front Mount Fixed – Wheel Loader – Class 40 | 2,300 lbs/1,043 kg | |

| DX-RCQ-HY-FFX-WL-50 | Rail Car Quick Coupler – Hydraulic – Front Mount Fixed – Wheel Loader – Class 50 | 2,300 lbs/1,043 kg | |

| DX-RCQ-HY-FFX-WL-60 | Rail Car Quick Coupler – Hydraulic – Front Mount Fixed – Wheel Loader – Class 60 | 2,400 lbs/1,089 kg | |

| DX-RCQ-HY-FFX-WL-70 | Rail Car Quick Coupler – Hydraulic – Front Mount Fixed – Wheel Loader – Class 70 | 2,400 lbs/1,089 kg | |

| DX-RCQ-HY-FFX-WL-80 | Rail Car Quick Coupler – Hydraulic – Front Mount Fixed – Wheel Loader – Class 80 | 2,400 lbs/1,089 kg | |

| Custom Rear Mount Models Available for certain machine models. Contact Dymax Rail for assistance. |

|||

| DX-RCQ-HY-RFS-WL-40 | Rail Car Quick Coupler – Hydraulic – Rear Mount Free Slide – Wheel Loader – Class 40 | 3,000 lbs/1,361 kg | |

| DX-RCQ-HY-RFS-WL-50 | Rail Car Quick Coupler – Hydraulic – Rear Mount Free Slide – Wheel Loader – Class 50 | 3,000 lbs/1,361 kg | |

| DX-RCQ-HY-RFS-WL-60 | Rail Car Quick Coupler – Hydraulic – Rear Mount Free Slide – Wheel Loader – Class 60 | 3,200 lbs/1,452 kg | |

| DX-RCQ-HY-RFS-WL-70 | Rail Car Quick Coupler – Hydraulic – Rear Mount Free Slide – Wheel Loader – Class 70 | 3,200 lbs/1,452 kg | |

| DX-RCQ-HY-RFS-WL-80 | Rail Car Quick Coupler – Hydraulic – Rear Mount Free Slide – Wheel Loader – Class 80 | 3,500 lbs/1,588 kg | |

| DX-RCQ-HY-RFS-WL-90 | Rail Car Quick Coupler – Hydraulic – Rear Mount Free Slide – Wheel Loader – Class 90 | 5,500 lbs/2,495 kg | |

Specifications are subject to change without notice.

Features:

- For wheel loaders and toolcarriers.

- Equipped with standard railroad cast knuckles.

- Choose from front or rear mount.

- Available in manual pin, hydraulic pin or pneumatic-air pin.

- Front mount models feature a pivoting knuckle and free slide assembly.

- Custom railcar coupler systems require welding and possible counterweight removal.